Zinc oxide (ZnO) nanowires (NWs) are excellent candidates for the fabrication of energy harvesters, mechanical sensors, piezotronic and piezo-phototronic devices thanks to the interplay between piezoelectric and semiconducting properties. The growth of ZnO NWs on flexible substrates would further broaden their possible applications. However, such a growth requires low temperature synthesis to prevent any damage to the flexible polymer. Another difficulty lies in the fact that the deposition of patterned ceramic thin films on flexible substrates is challenging, especially under vacuum free conditions. In this framework, printing technologies like inkjet and gravure printing have a noteworthy potential since they allow to deposit thin films onto flexible substrates and offer several other advantages like cost efficiency, use of low temperatures, high throughput and the capability of patterning during the deposition process.

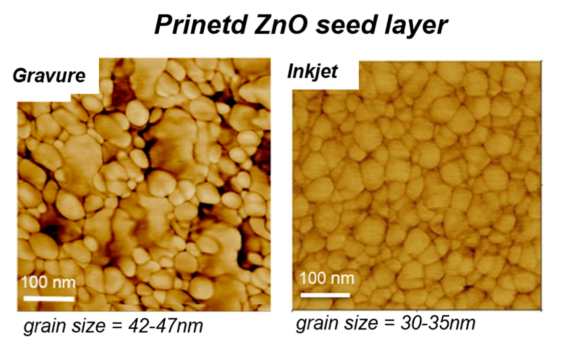

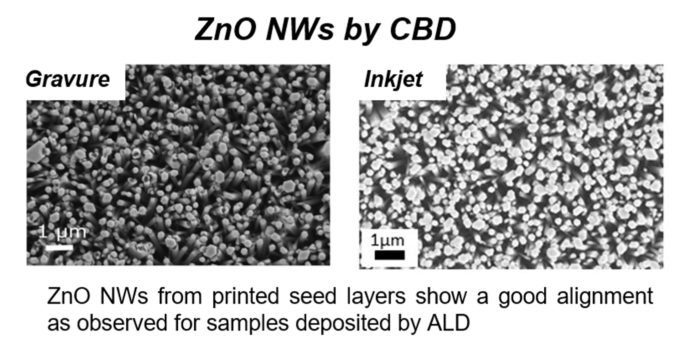

In our study we demonstrated the possibility to realize uniform ZnO nanoparticles-based seed layers on polyethylene terephthalate (PET) substrate by gravure- and/or inkjet-printing techniques (Figure 1) and then grow high quality ZnO NWs by applying a chemical bath deposition (CBD) process (Figure 2).

Figure 1: AFM phase images of gravure- and inkjet-printed ZnO seed layers onto ITO/flexible substrate.

Figure 2: SEM images of ZnO NWs grown by applying the CBD process to gravure- and inkjet-printed ZnO seed layers.

For both deposition technologies, we observed, through Piezoresponse Force Microscopy (PFM) analysis, that the Zn-polar domains are homogeneously distributed at the top surface of the grown ZnO NWs in perfect agreement as detected in samples realized by conventional methods as Atomic Layer Deposition (ALD).

This research demonstrates the key benefit of the printing techniques over other deposition methods to deposit seed layers at low temperatures on flexible substrates so opening the root to manufacture vacuum-free solution-based flexible piezoelectric devices.

PULSE-COM articles related to the ZnO seed layer deposition by means gravure- and/or inkjet-printing techniques:

https://www.mdpi.com/2079-4991/11/6/1430

https://www.mdpi.com/2673-706X/2/2/8

https://spie.org/Publications/Proceedings/Paper/10.1117/12.2666645?SSO=1