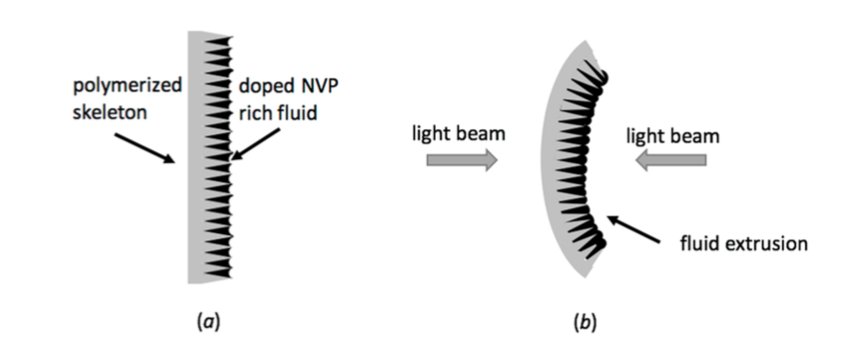

The use of stimuli-responsive polymeric materials is nowadays a hot topic because of their immense application possibilities. The deformation of PMP are intended to be induced and controlled by impinging ligth by its intensity, polarization state, wavelength. Specifically, PMP actuators change their shape or volume in response to light [1]. We have developed two different PMP films: Interfacial tension gradient-based PMP films (PMP-r) and Azo-benzene based liquid crystals PMP films (Azo-LC-PMP).

PMP-r (“r” for auto-“restoration”, since it restores its initial position without the necessity of an additional external source of light: in darkness) has been recently ideated and developed based on the interfacial tension gradient between layers [2-3]. The polymer restoration (that is the restoration of the starting position/3D configuration of the PMP) should be regulated by diffusion/capillarity.

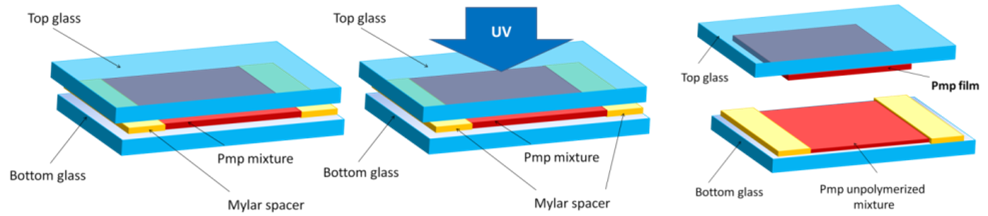

Figure 1: Top left – Sketch of the working mechanism of photomobile polymer (PMP) based on mixture of multi-reticulated acrylate polymers and N-Vinyl-Pirrolidone (NVP) doped: (a) before light irradiation; (b) under light irradiation (from either side of the film). Top rigth – Large PMP-r film before the peeling off procedure. Bottom – Scheme for the photopolymerization of PMP-r film and subsequent peeling-off of the film [2-3].

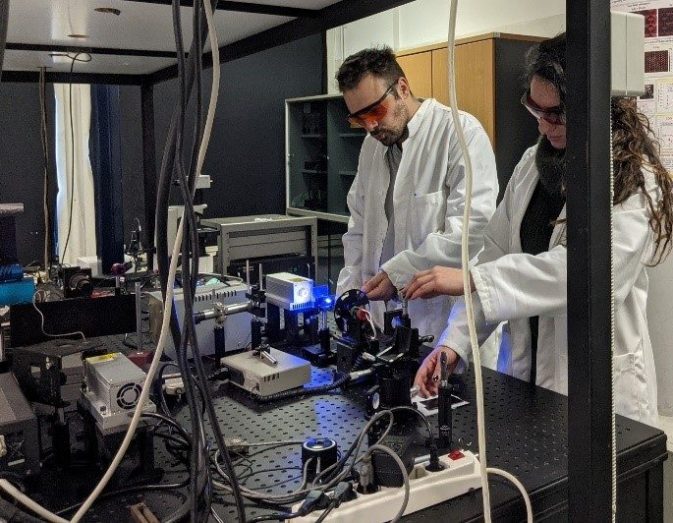

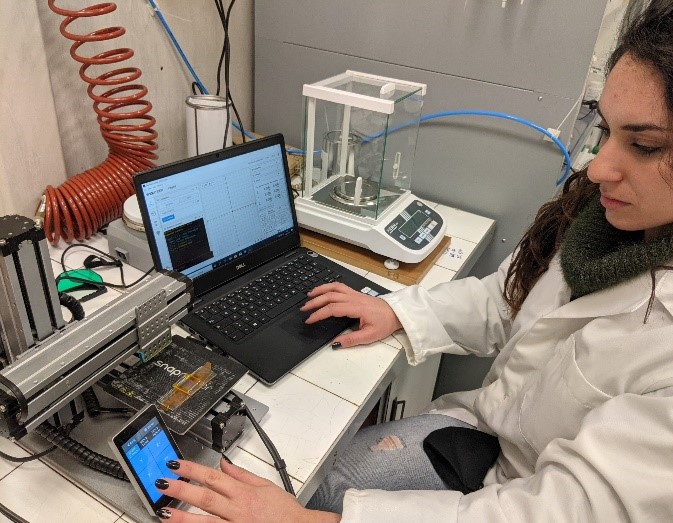

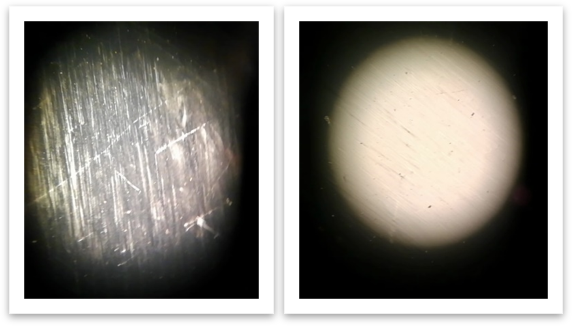

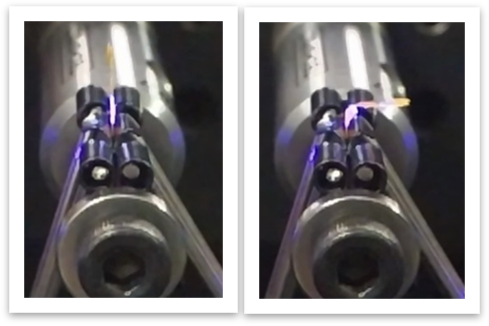

Azo-benzene based liquid crystals PMP films (azo-LC-PMPs): the mechanism responsible for the light-induced bending azo-LC-PMP is the cis-trans photo-isomerizations leading to the film deformation at a macroscopic level. In particular, liquid crystalline based materials with the inclusion of azobenzene moieties respond with 3D movement to polarized light. Showing applicabilities to various fields, e.g. microrobotics, energy harvestings. The production of these photo-mobile polymer materials depend on the grade of internal organization of the azobenzene moieities. In fact it is fundamental to allineate the LCs towards a common vector in their nematic phase. In our laboratories we use micro-reactor rubbed cells, produced using glass slides coated with a thermoplastic polymer. The coated glass is rubbed unidirectionally using a PC controlled electronic arm. The acrylate-LCs are thermically infitrated in the cell and polymerized at nematic conditions. Currently we are optmizing formulations and methodology for prepration an characterization of photoresponsive cantilevers.

Figure 2: Top left – CNR scientists characterizing PMPs based on azobenzene. Top right – automated rubbing procedure. Bottom left – polarized light rotation by an aligned LC. Bottom right – PMPs bending toward the polarized light.

[1] M. Yamada, M. Kondo, J. Mamiya, Y. Yu, M. Kinoshita, C. J. Barrett, T. Ikeda “Photomobile polymer materials: towards light-driven plastic motors”, Angewandte Chemie International Edition, 2008, 47, 4986–4988.

[2] R. Castagna, L. Nucara, F. Simoni, L. Greci, M. Rippa, L. Petti, D. E. Lucchetta, “Plasmonic Photomobile Polymer Films”, Advanced Materials, 2017, 29, 1604800.

[3] R. Castagna, M. Rippa, F. Simoni, F. Villani, G. Nenna, L. Petti, “An Unconventional Approach to Photomobile Composite Polymer Films”, Crystals 2020, 10, 660; doi:10.3390/cryst10080660