Piezoelectric semiconducting nanowires have attracted a lot of attention recently because of their intrinsic enhanced properties compared to bulk materials. For instance, they are more sensible to small forces [1], they show reduced dielectric properties [2] and higher piezoelectric properties [3]. All this combined could potentially increase their efficiency as transducers [4]. Simulations show that when integrated into nanocomposites (i.e., the nanowires are immerged into a dielectric matrix and contacted by bottom and top electrodes), they could present improved performances when compared to thin films [5]. Morover, ZnO is an abundant, biocompatible material, thus it is a good candidate to replace actual piezoelectric materials containing lead. For all these reasons, they are an excellent choice for applications, such as energy harvesters, mechanical sensors, piezotronic and piezophototronic devices [6]. Even more, low temperature growth methods allow these nanostructures to be easily integrated into flexible or rigid substrate and then operated under bending or compressive forces [7]. Within PULSE-COM, UGA is developing ZnO based nanocomposites for novel photo-piezo-actuators devices and applications. Many challenges need to be addressed in this context, for example: the compatibility between the composite and the different substrates, the growth of NWs with specific ZnO seed layers and the improvement of the performance.

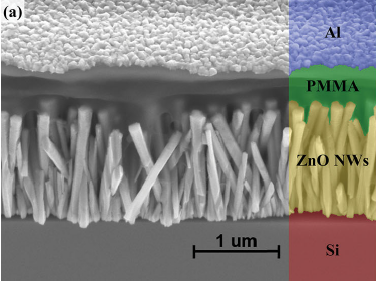

Figure 1: SEM cross-section view of a ZnO based nanocomposite integrated on a rigid substrate [8].

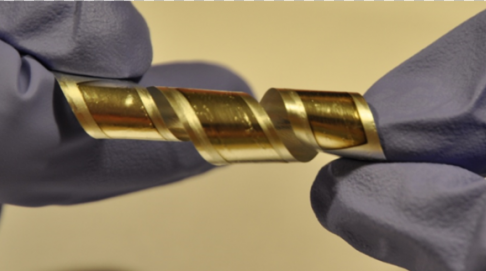

Figure 2: A ZnO based nanocomposite integrated onto a flexible substrate. Adapted from [9].

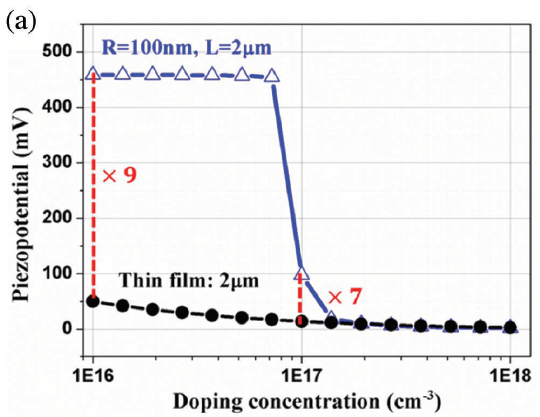

Figure 3: Simulations results of ZnO based nanocomposites vs. a ZnO thin film evaluated under compressive forces [10].

[1] G. Cheng, C. Miao, Q. Qin, et al., Nature nanotechnology, 10( 8), p. 687 2015.

[2] Y. Yang, W. Guo, X. Wang, Z. Wang, J. Qi et al., Nano letters, 12(4), p. 1919-1922 2012.

[3] M. Minary-Jolandan, R. A. Bernal, I. Kuljanishvili, V. Parpoil et al., Nano letters, 12(2), p. 970-976 2012.

[4] R. Tao, G. Ardila, R. Hinchet, A. Michard, L. Montès, and M. Mouis, “Will composite nanomaterials replace piezoelectric thin films for energy transduction applications?”, in Future Trends in Microelectronics: Journey into the Unknown; Wiley, John & Sons, Inc. 2016. DOI: 10.1002/9781119069225.ch3-4.

[5] R. Tao, M. Mouis and G. Ardila, Adv. Electron. Mater., 4(1), p. 1700299 2018.

[6] Y.S. Zhou, R. Hinchet, Y. Yang, G. Ardila, R. Songmuang, F. Zhang, Y. Zhang, W. Han, K. Pradel, L. Montes, M. Mouis and Z.L. Wang, Adv. Mater., 25, 6, p. 883-888 2013; R. Tao, G. Ardila L. Montes and M. Mouis, Nano energy, 14, p.62-76 2015

[7] R. Tao, M. Parmar, G. Ardila, P. Oliveira, D. Marques, L. Montès and M. Mouis, Semicond. Sci. Technol., 32(6), p. 064003 2017 ; D. Menin, M. Parmar, R. Tao, P. Oliveira, M. Mouis, L. Selmi & G. Ardila, In IEEE Joint International EUROSOI Workshop and International Conference on Ultimate Integration on Silicon (EUROSOI-ULIS), March 19-21, Granada, Spain (pp. 1-4). (Poster) 2018

[8] R. Hinchet, S. Lee, G. Ardila, L. Montes, M. Mouis, Z. L. Wang, “Performance Optimization of Vertical Nanowire-Based Piezoelectric Nanogenerators”, Adv. Funct. Mater., 24, p. 971-977 2014. DOI: DOI: 10.1002/adfm.201302157

[9] S. Lee, R. Hinchet, Y. Lee, Y. Yang, Z.-H. Lin, G. Ardila, L. Montes, M. Mouis, Z. L. Wang, “Ultrathin Nanogenerators as Self-powered/Active Skin Sensors for Tracking Eye Ball Motion”, Adv. Funct. Mater., 24, p. 1163-1168 2014. DOI: https://doi-org.gaelnomade-2.grenet.fr/10.1002/adfm.201301971

[10] R. Tao, M. Mouis and G. Ardila, Adv. Electron. Mater., 4(1), p. 1700299 2018.